In the food and beverage industry, nitrogen is primarily used for packaging, preservation and quality enhancement. It displaces oxygen in packaging ang significantly extends the shelf life of perishable items by slowing down oxidation and bacterial growth. Furthermore, nitrogen is used in the carbonation process of beverages like beer and soft drinks and its inert properties make it ideal for creating a controlled atmosphere in food processing and storage.

In the industry, nitrogen gas was historically delivered in high-pressure cylinders or liquid nitrogen containers. However, there has been a shift towards on-site nitrogen production using nitrogen generators due to the numerous benefits they offer. Nitrogen generators are machines used to produce nitrogen gas and work by separating nitrogen from other gases present in the compressed air. The process by which the nitrogen is produced is called pressure swing adsorption (PSA) or by using membrane technology.

What are the benefits of nitrogen in food and beverage industry?

One of the most significant benefits of using nitrogen is that it extends the shelf life of food products. This is because nitrogen gas creates an oxygen-free environment, which prevents the growth of bacteria and other microbes that cause decay and spoilage. Furthermore, nitrogen gas can also help improve the flavor and texture of food and beverages. By reducing the amount of oxygen present in food packaging, it can prevent oxidation and preserve the freshness of the product.

Modified atmosphere packaging (MAP) proccess

To highlight, nitrogen is used in various applications within the food and beverage industry, including:

- Modified Atmosphere Packaging (MAP): Nitrogen is used to replace oxygen in food packaging, extending shelf life and preserving freshness, flavor, and color.

- Controlled Atmosphere Storage (CAS): Nitrogen helps in preserving the quality of stored food items, particularly in large storage facilities. It regulates the levels of oxygen, carbon dioxide, and nitrogen, along with temperature and humidity.

- Beverage Production: Nitrogen is used in carbonating beverages like beer and soft drinks.

- Freezing and Chilling: Liquid nitrogen is used for rapid cooling and freezing of food products, preserving their texture and nutritional value.

- Bakery Products: Nitrogen is used in packaging bakery items to maintain freshness and extend shelf life.

- Snack Food Packaging: It’s used to inflate snack bags, providing cushioning to protect the contents and displacing oxygen to extend shelf life.

- Dairy Products: Nitrogen is used in the packaging of dairy products to preserve quality and freshness.

- Cooking Oil Preservation: Nitrogen is passed through cooking oils to reduce oxygen and thus prolong the oil’s usability.

- Inerting and Purging: Nitrogen is used to create an inert atmosphere in storage tanks and production areas to prevent oxidation and other reactions.

- Sparging: This process involves bubbling nitrogen through liquid food products to remove dissolved gases.

We may often overlook the significance of nitrogen in our everyday lives, however its impact is found in many food and beverages that we consume daily. In this regard, nitrogen is key in Modified Atmosphere Packaging (MAP), a process that keeps our foods like cheese, bread, and snacks fresh for longer periods. In beverages, nitrogen distinctively transforms the texture and taste of craft beers. It also helps in preserving the quality and flavor of wines and in keeping roasted coffee beans fresh.

How food and beverage industry supplies nitrogen?

As mentioned in the introduction, nitrogen gas supply in the food and beverage industry primarily involved high-pressure cylinders or liquid nitrogen containers. However, a shift towards in-house nitrogen generation systems has become more prominent, attributed to multiple benefits such as efficiency, cost reduction, physical space and sustainability. Consequently, many companies choose to go with on-site nitrogen generators as they offer continuous supply of nitrogen, reduce dependency on external suppliers, and are more cost-effective in the long run. However, depending on the size of the factory, needs and infrastructure, etc nitrogen in the industry is supplied through four methods:

Nitogen Cylinders

Bulk Nitrogen Gas Systems: Larger facilities may use bulk gas systems, which involve the delivery (gaseous state) and storage of nitrogen in large quantities, typically in cryogenic tanks.

Nitrogen Generators: On-site nitrogen generation systems are becoming increasingly popular. These systems extract nitrogen from the air using technologies like Pressure Swing Adsorption (PSA) or membrane separation.

Liquid Nitrogen Tanks: Liquid nitrogen is supplied in bulk tanks. The liquid nitrogen is vaporized into gas before use.

Cylinder Supply: High-pressure cylinders are one of the most traditional methods. Nitrogen gas is stored in these cylinders under high pressure and is delivered to the site as needed.

Nitrogen generators

Within the possibility of on-site nitrogen generation, there are two main technologies used in nitrogen generators: Pressure Swing Adsorption (PSA) and Membrane technology, as we will highlight below:

Pressure swing adsorption Nitrogen (PSA) technology

PSA technology works by separating nitrogen from other gases present in compressed air through a selective adsorption process. The compressed air is passed through a bed of carbon molecular sieves (CMS), where oxygen and other gases are selectively adsorbed onto the surface of CMS, while nitrogen passes through the bed and is collected for use.

Membrane Nitrogen technology

Membrane technology works by utilizing a selectively permeable membrane to separate nitrogen from other gases in compressed air. Compressed air is passed through a membrane that allows nitrogen to pass through while other gases are trapped and separated.

What benefits do nitrogen generators offer to the food and beverage industry?

Apart from covering all the applications mentioned above, both PSA and membrane technologies offer significant benefits to the food and beverage industry such as:

- Cost Efficiency: Nitrogen generators reduce ongoing costs associated with delivery, transportation, and rental fees for cylinders or liquid nitrogen.

- Continuous Supply: They provide a consistent and uninterrupted supply of nitrogen, eliminating the need for regular deliveries and the risk of running out.

- Safety: On-site generators are generally safer than handling high-pressure cylinders or liquid nitrogen, reducing the risk of accidents related to storage and handling.

- Environmental Benefits: Generating nitrogen on-site reduces the environmental impact associated with the transportation of nitrogen in cylinders or liquid form.

- Space Savings: They require less storage space compared to storing a large number of cylinders or large liquid nitrogen tanks, freeing up valuable floor space in facilities.

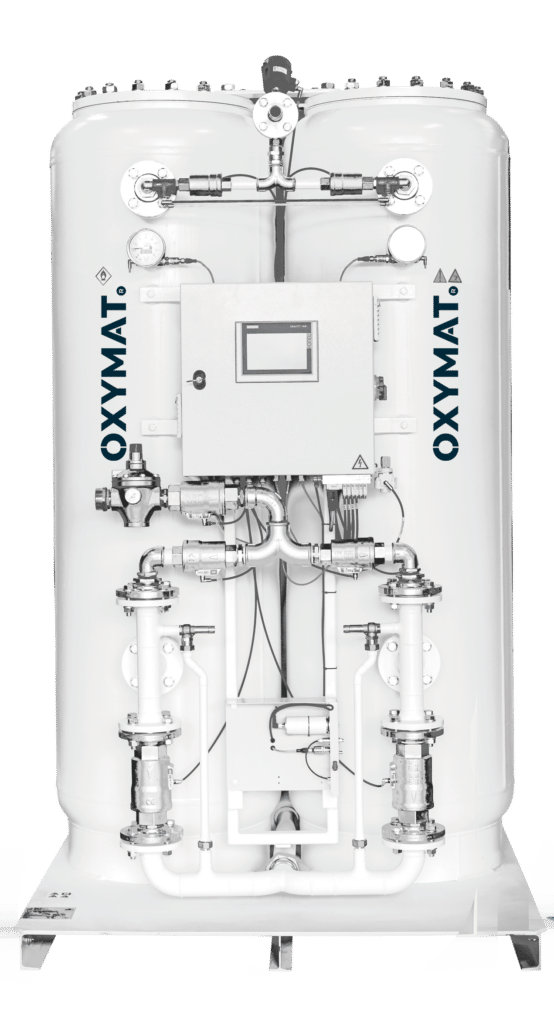

Nitrogen generators from OXYMAT

OXYMAT’s range of nitrogen generators offers a practical and efficient solution for on-site nitrogen production in the food and beverage industry. This range includes:

- The Nordic Series: Featuring PSA technology, it is designed for energy efficiency and cost-effectiveness, with a flow capacity that can exceed 4500 m³/h. This makes it suitable for various operational scales, from small to large-scale food and beverage production.

- Membrane Solutions: These are particularly compact, boasting the world’s smallest footprint for a nitrogen generator at 635 m³/h. Designed for minimal maintenance, they are ideal for facilities of all sizes, where space and ease of operation are key considerations.

- Industry Standard PSA – Twin Tower: Delivers high nitrogen purity, higher than 99.9%. This level of purity is essential for maintaining the quality and freshness of food and beverage products, especially in sensitive applications.

Together, these generators from OXYMAT offer seamless integration into existing operations, providing a steady and on-demand supply of nitrogen. This reduces the reliance on external nitrogen sources and enhances the overall efficiency of production processes in the food and beverage industry and other industries using nitrogen generators such as marine.

LEARN MORE ABOUT OUR NITROGEN GENERATORS HERE

In summary, the role of the nitrogen in the food and beverage industry is very important, primarily for its properties used in preservation and enhancing product quality. Nitrogen is used in various applications such as Modified Atmosphere Packaging (MAP), beverage carbonation, and food storage, among others.

Factories within the industry will traditionally supply their nitrogen through high-pressure cylinders or liquid nitrogen containers. However, the industry is increasingly shifting toward on-site nitrogen production i.e. nitrogen generators for their efficiency, cost-effectiveness and sustainability.

Nitrogen generators use advanced methods like Pressure Swing Adsorption (PSA) and membrane separation to provide a better way of producing nitrogen. They are cost-effective, supply nitrogen continuously, are safer, better for the environment, and save physical space. OXYMAT offers several types of these generators, including the Nordic Series, Membrane Solutions, and the Twin Tower model. These systems produce continuous and very pure nitrogen, up to 99.99%. Regardless of the size of the operation and facility, they can easily be fitted into production processes.