One of the main concerns of the transportation of crude oil, clean products and liquefied gases by tankers has been the necessity to secure the cargo from accidents such as fires and explosions. However, ensuring a safe voyage for tankers is not a concern limited solely to the oil and gas industry; it extends to many coastal countries and environmental protection organizations as well. Consequently, vessels involved in the transportation of crude oil, clean products and gases are subject to very strict building standards that prioritize both safe transportation and environmental protection. Since 1974, regulations under SOLAS (Safety of Life at Sea) mandate that all oil and gas transportation vessels must have inert gas systems capable of generating inert gas with an oxygen content not exceeding 5% by volume.

Additionally, all ships exceeding dwt (deadweight tonnage) of 8,000 are required to have inerting systems and to maintain a pressure inside the tanks higher than the surrounding atmosphere while ensuring that the air inside the tank contains no more than 8% oxygen by volume. Today, ships transporting oil, clean products and liquefied gases use three different methods to secure inert gas: flue gas systems, which utilize ship engine exhaust gases; inert gas generators, which produce inert gas by burning fuel; and nitrogen inerting systems, which generate high-purity nitrogen through nitrogen generators to ensure cargo tank inerting. The application of nitrogen becomes highly relevant in this context, particularly because of its unique properties and environmental regulations.

What kind of inerting systems are utilized in marine?

As mentioned above the marine industry relies on three main inerting systems to establish inert atmosphere within cargo tanks. Each of these approaches employs unique techniques to ensure cargo safety during transportation:

Inert gas generator system

How it works

Inert Gas Generators operate by combusting fuel within specially designed generators, resulting in exhaust gases rich in carbon dioxide (CO2). These gases are then carefully processed to remove impurities like oxygen and vapor, ensuring that the gas’s quality meets the necessary standards for safe usage in the cargo tanks.

Flue gas inerting system

How it works

FGIS relies on utilizing the exhaust gases produced by the ship’s engines, which already contain a significant amount of CO2. The produced gases are then additionally processed to remove any remaining oxygen and impurities before being introduced into the cargo tanks.

Nitrogen inerting generation system

How it works

Nitrogen generators, such as Pressure Swing Adsorption (PSA) or Membrane Nitrogen Generators, are separate systems that are installed on ships. They produce high-purity nitrogen gas from the surrounding air. The generated nitrogen is then carefully directed into the cargo tanks to reduce the oxygen levels and create an inert atmosphere.

How is nitrogen used on marine vessels?

Due to its unique properties, such as high compressibility, inert characteristics, and miscibility with water, the use of nitrogen as an inert gas has become the preferred choice on many vessels in the marine industry. Here are som keyways in which nitrogen is employed on the vessels:

Inerting fuel tanks

Nitrogen is used to create an inert atmosphere inside fuel tanks. The air (containing oxygen, necessary for combustion) inside tanks is replaced with nitrogen. By doing this, the risk of fire or explosion due to any fuel vapors inside the tank is greatly reduced.

Purging pipelines

Pipelines in the oil and gas industry often contain flammable gases, hydrocarbons, or other contaminants. Nitrogen is used to purge pipelines, which means flushing them with nitrogen to push out any potentially dangerous substances.

Pressure testing

Nitrogen is employed for pressure testing of the pipelines and equipment’s. The process is similar to checking automobile tires for punctuations.

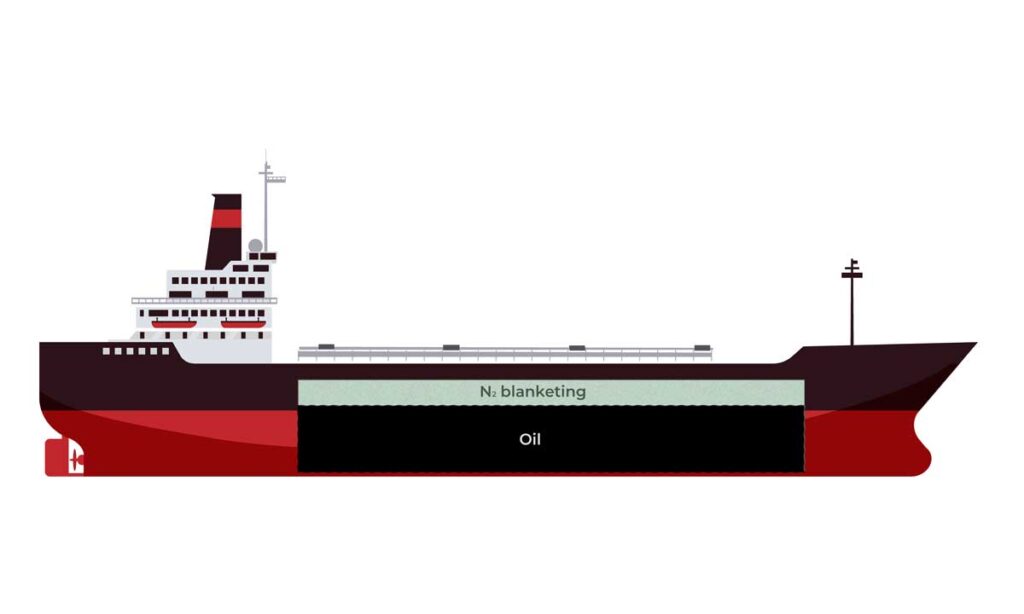

Blanketing

In storage tanks where liquids like crude oil or refined products are kept, nitrogen is used to create a ‘blanket’ over the liquid’s surface. Nitrogen blanket displaces the air and prevents oxygen from coming into contact with the liquid. As oxygen can cause corrosion and support combustion.

Stripping

On ships, especially those transporting crude oil and clean products, it’s essential to ensure that cargo tanks are thoroughly cleaned and free from any previous cargo or gases before loading a new cargo. Nitrogen is introduced into the cargo tanks to ‘strip’ away any residual gases or liquids, effectively making the tanks clean and safe for the next cargo.

What benefits do nitrogen gas generators offer marine vessels?

Ensuring efficiency on carriers is of paramount importance, and nitrogen gas generators play a crucial role in this process. They offer numerous advantages, including enhanced quality, 24/7 nitrogen production and environmental protection, among others. The generators are typically of a modular design, making them highly adaptable to physical space and capacity needs.

|

|

Benefits |

|

Safety |

Nitrogen generators create inert atmospheres, reducing the risk of combustion or explosions on oil and gas ships |

|

Regulatory Compliance |

Nitrogen generators enable compliance with international regulations (e.g., SOLAS) by producing inert atmospheres with low oxygen content. |

|

Cargo Quality Control |

Nitrogen generators maintain cargo quality by creating nitrogen blankets that prevent oxidation and contamination during transport. |

|

Environmental Protection |

Nitrogen generators help in meeting strict environmental standards set by ports, environmental organizations, and coastal nations. |

|

Operational Efficiency |

On-demand 24/7 nitrogen production eliminates the need for transporting and handling nitrogen cylinders, reducing logistical complexities and costs. |

|

Adaptability |

Nitrogen generators can be customized for different vessel sizes and operational requirements. |

|

Emergency Shutdown |

In emergencies or fires, nitrogen generators create inert atmospheres, aiding in shutdown and safety procedures. |

|

Reduced Carbon Footprint |

Producing nitrogen on-site with generators reduces the carbon footprint associated with producing inert gases. |

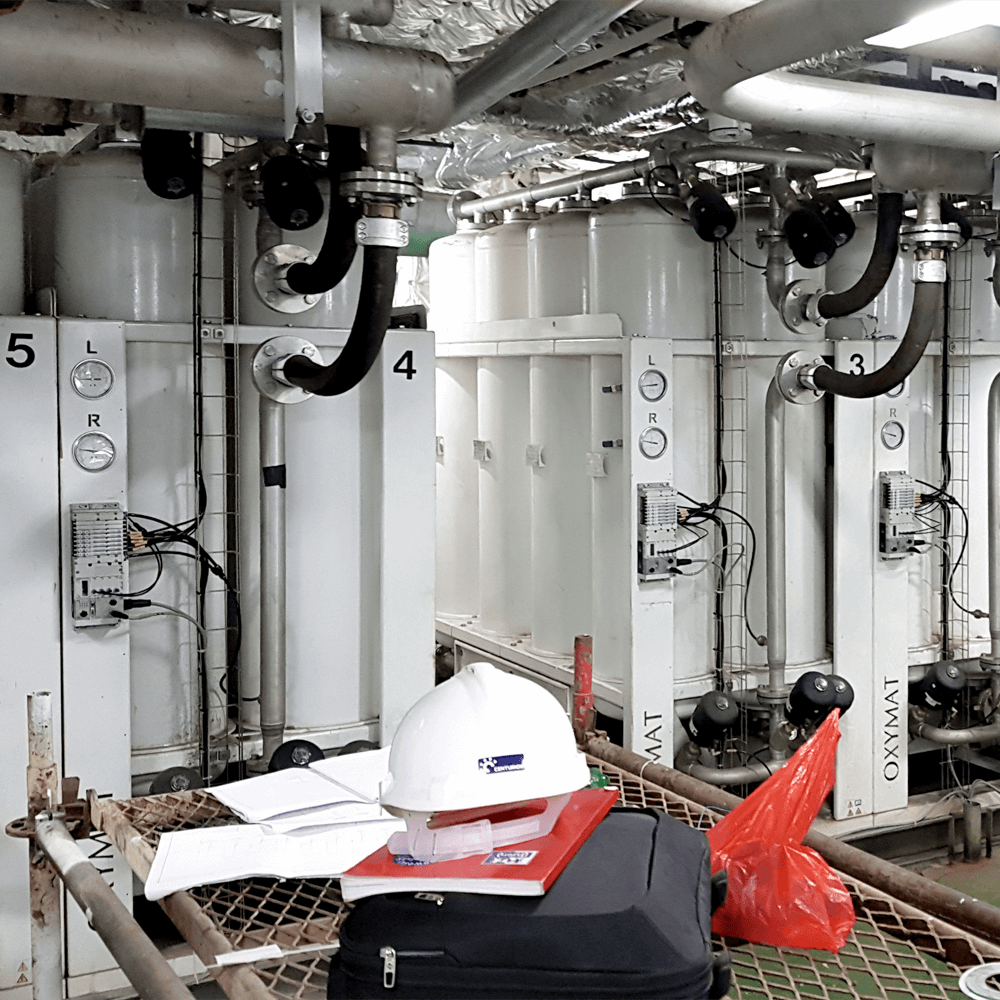

Depending on the size of the vessels and the required nitrogen capacity, marine industry carriers employ two primary types of generators, which are:

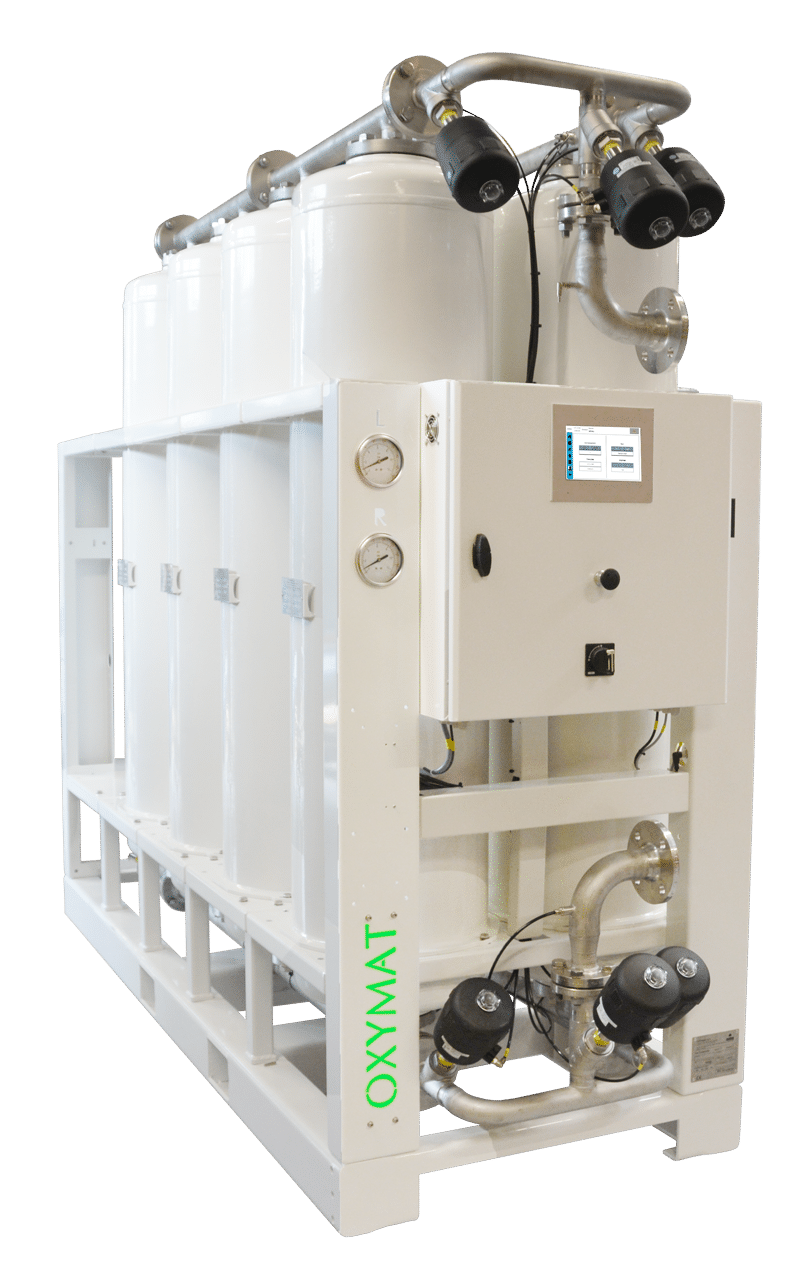

Membrane nitrogen generators

Generators use semi-permeable membrane technology to separate nitrogen from the surrounding air. Compressed air is passed through the membrane, which allows nitrogen molecules to pass through while other gases like oxygen and water vapor are vented out. Membrane nitrogen generators are usually applied when requirements for nitrogen purity levels are not that high.

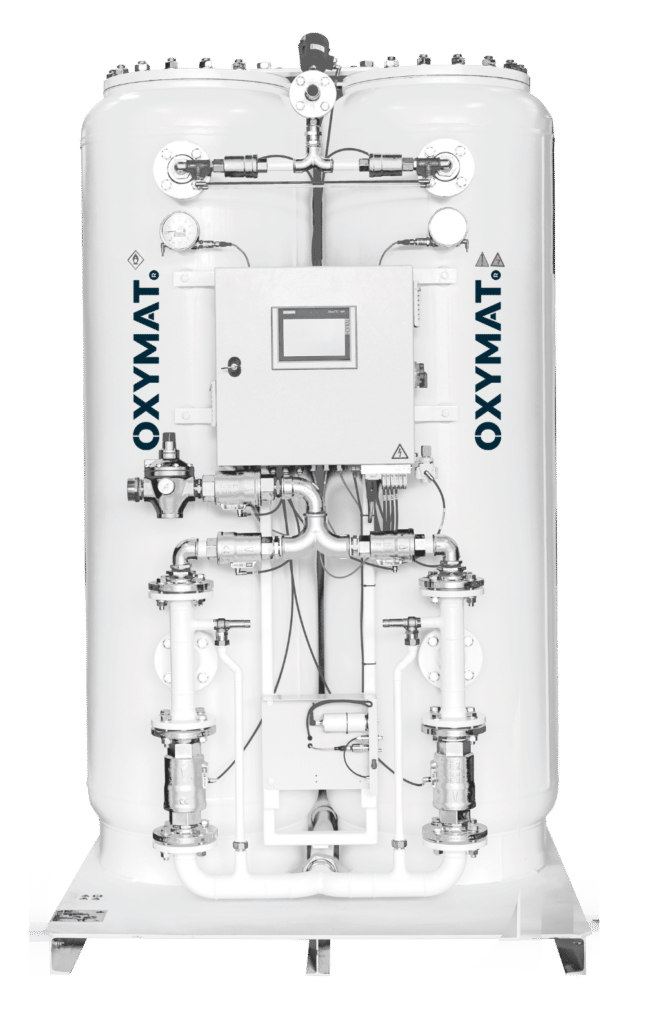

Pressure swing adsorption (PSA) nitrogen generators

PSA nitrogen generators use adsorption technology to separate nitrogen from air. PSA generators can produce high-purity nitrogen and are commonly used when strict purity requirements must be met.

In some cases, vessels may employ a combination of both types, however that depends on purity needs, efficiency, regulations and cost-effectiveness.

The green advantage – nitrogen generators, environment and cargo quality at ports

Nitrogen generators provide a substantial advantage in preserving cargo quality, specifically when vessels are anchored at a port. Unlike inert gas generators and flue gas systems, which rely on gases from combustion, nitrogen generators operate independetely of ship engines with very low emissions. Nitrogen generators ensure compliance with the existing environmental requirements and help in aligning with future port sustainability goals, such as those set by EU and IMO (International Maritime Organization).

In 2021, the EU Green Deal has set a target of achieving a 90% reduction in emissions for EU port cities by 2050. Similarly, the IMO set a CO2 reduction goal for international shipping. This goal demands a minimum of 40% reduction in CO2 emissions by 2030, with further efforts aimed at achieving a 70% reduction by 2050.

Oxymat’s nitrogen generators

One of the companies that produces nitrogen generators, that also meets port and environmental requirements is OXYMAT. OXYMAT is a manufacturer that specializes in the production of both PSA and membrane nitrogen generators that are also used in other industries such as food and beverage industry. Two models that stand out are:

N200-5 nitrogen generator

Among OXYMAT’s PSA nitrogen generator offerings, the N200-5 stands out as an exceptional choise for the marine. Its features include compact design and modular adaptability. Its low comsumptions energy aligns seamlessly with the marine industry’s sustainability objectives.

Membrane nitrogen solution

OXYMAT also provides a reliable membrane nitrogen solution. The generator offers flexible installation, requires minimal maintenance, and has a quick warm-up time. It features are the world’s smallest footprint and holds all major marine approvals.

Learn more about OXYMAT Nitrogen Generators →

In summary, to ensure safety during transportation of oil, clean products and other hazardous materials, vessels in the marine industry employ three main inerting systems, they are:

Inert gas generator systems, flue gas inerting systems and nitrogen inerting systems.

Nitrogen generation system that employ Pressure Swing Adsorption (PSA) and Membrane technology can gain significant importance, which in addition to safety they offer easier regulatory compliance and provide environmental benefits.

In line with the 2021 EU Green Deal, which targets a 90% emsissions reduction in EU port cities by 2050, and the outlined CO2 reduction targets for intenational shipping by the IMO, nitrogen generators, as those from OXYMAT, play an important role in attaining these environmental goals.

OXYMAT, a renowned nitrogen generator manufacturer, offers solutions such as the N200-5 nitrogen generator and a dependable membrane nitrogen solution. They are designed to easily incorporate with ship’s build and meet the strict environmental requirements of the marine industry. Thanks to their modular construction and retrofitting capacity, OXYMAT’s nitrogen generator systems can become an ideal choice for current and future vessels.