Aquaculture

Oxygen application

OXYMAT oxygen generators for aquaculture will optimise your production. In recent years, oxygen usage in aquaculture has risen drastically. So, now more than ever it makes sense to look at your operation costs.

OXYMAT oxygen generators for aquaculture or fish farming will optimise your production. In recent years, oxygen usage in aquaculture has risen drastically. So, now more than ever it makes sense to look at your operation costs.

World’s largest well boat

OXYMAT delivered the oxygen package for Ronja Storm. The system has a capacity of 4 x 98 kg/hr.

World’s largest smolt station

OXYMAT delivered the oxygen package for Bakkafrost’s smolt station in the Faroe Islands. The system consist of 7 full lines – each with a capacity of 650 kg/hr.

Quick ROI (1-2 years)

Power consumption is more than 40% lower than any other oxygen generator on the market. Overall cost reduction up to 80% in comparison with cylinders. No on-going costs (refills, delivery and transportation charges etc.)

Applications include

Applications include

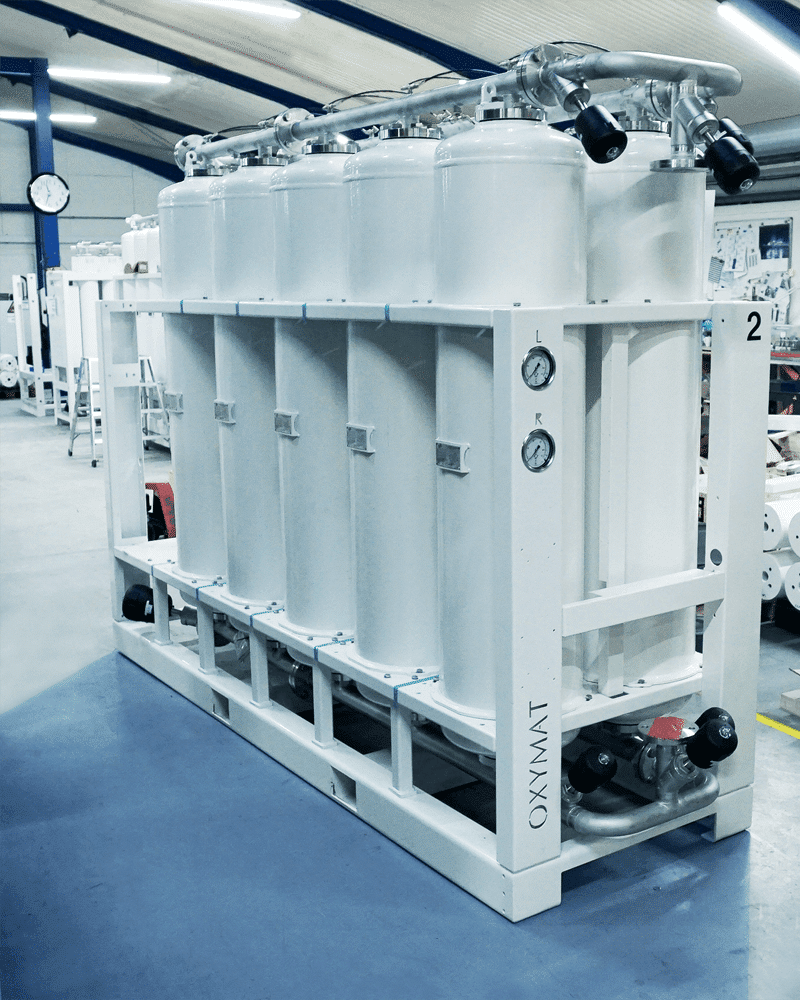

- PSA generators can supply oxygen for all aquaculture applications

- Our models range from 2.4 to 576.42 kg/h

- Modular design that can be upscaled if capacity need change

- All pressure vessels are sandblasted and powder coated P265 in C4 grade for extended lifetime and reduced maintenance

- PSA generators can supply oxygen for all aquaculture applications

- Our models range from 2.4 to 576.42 kg/h

- Modular design that can be upscaled if capacity need change

- All pressure vessels are sandblasted and powder coated P265 in C4 grade for extended lifetime and reduced maintenance

Advantages of OXYMAT oxygen generators

Advantages of OXYMAT oxygen generators

- No safety risks of handling high-pressure cylinders

- Safe delivery; controlled flow and uninterrupted gas

- Easily installed in addition to any existing oxygen supply (cylinders, cryogenic or other PSA systems)

- Generate the O2 you need, when and where you need it

- Very low OPEX compared to cylinders or liquid gas

- Remove the hassle of handling cylinders

- No need to rely on external gas suppliers and fluctuating prices

- Advanced central control system carefully operates the system ensuring the desired oxygen quantity and quality is supplied

- System can be containerised and placed outside – even in extreme temperatures

- No safety risks of handling high-pressure cylinders

- Safe delivery; controlled flow and uninterrupted gas

- Easily installed in addition to any existing oxygen supply (cylinders, cryogenic or other PSA systems)

- Generate the O2 you need, when and where you need it

- Very low OPEX compared to cylinders or liquid gas

- Remove the hassle of handling cylinders

- No need to rely on external gas suppliers and fluctuating prices

- Advanced central control system carefully operates the system ensuring the desired oxygen quantity and quality is supplied

- System can be containerised and placed outside – even in extreme temperatures

Quality

To learn more about our approach to quality, please visit our quality page

To learn more about our approach to quality, please visit our quality page