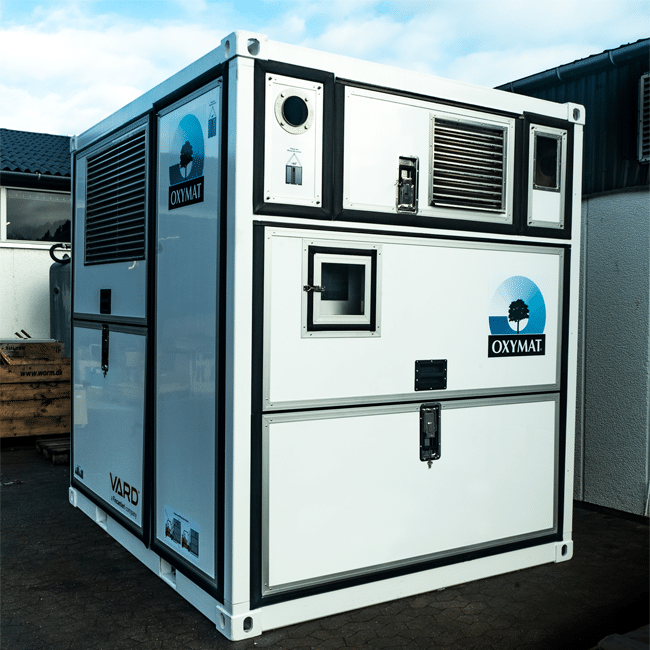

A new Danish design classic is born!

The innovative new unit is a complete game changer. The unit is compact and flexible in use and transportation. The figures speaks for themselves. Incredible capacity from an exceptionally compact plug-n-play solution.

Clever design – Quality workmanship

Every single component in the unit is carefully chosen or designed to minimize the footprint, weight or power consumption. Pipe-sets are handmade from ss316l and all sub-suppliers are top tier in their respective field.

- 65 kg/h @ 93%

- 45 kW

- Ultra lightweight

- Prepared for harsh environments

- Remote monitoring

- Temperature control

- Plug-n-Play